MAKING THE MOST OUT OF WASTE AND WATER

Let’s first start with some context!

Keeping planet Earth livable, arguably the most urgent and important task we have as a species, is about much more than just reducing carbon emissions. Between the 'COP21 in Paris’, and COP26 in Glasgow (6 yrs) 70% more virgin materials were extracted than what the Earth can safely replenish.

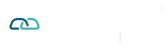

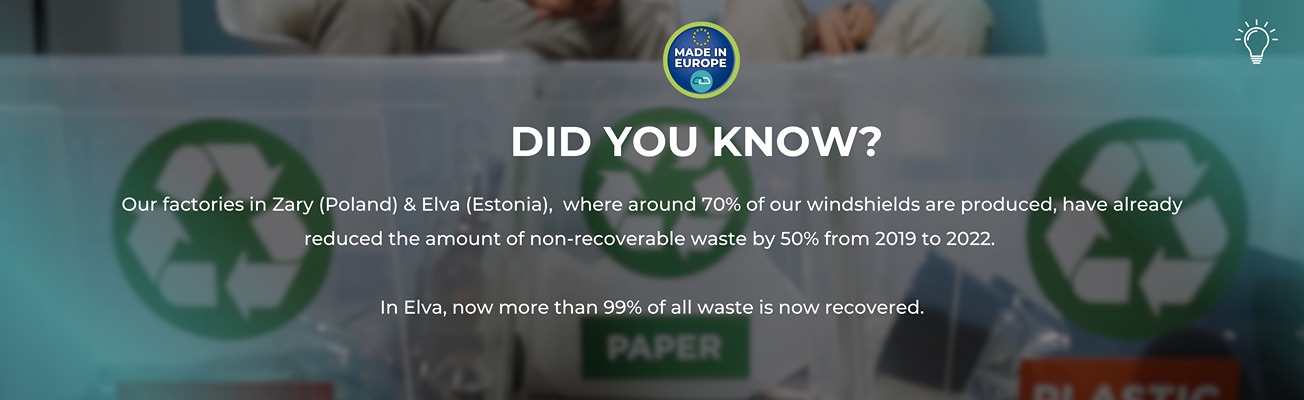

From reducing the extraction of natural resources and realising a full circular economy, to preserving the planet’s natural ecosystem; what’s needed is a holistic approach. Which is exactly what we aim to do at Sekurit Service. Not in some distant future, but now. That’s why we have concrete goals to reduce the amount of non-recoverable waste to 0 by 2030 and to close the water loop.

A CLEAR VIEW OF A CLEANER FUTURE

A CLEAR VIEW OF A CLEANER FUTURE

While our previous Made in Europe newsletter was mainly focused on our view of, and contributions to, the circular economy, we’d like to tell you a bit more about two important topics in that area: waste and water.

At Sekurit Service, our view of the future is clear: more recycling, more reuse, no more waste and plants with limited impacts on the environment. Ambitious? Absolutely. Unattainable? Not if we do this together with all our employees, stakeholders and partners. In fact, we already are doing this. From increasing the amount of used glass into the production of new glazing, to collecting waste from our customers, and from limiting water withdrawal to training our employees on best practices; we’re driving sustainability.

THE GROWTH IN GLOBAL WASTE

According to the World’s bank’s “What a waste 2.0” report, global annual waste generation is expected to jump to 3.4 billion tonnes over the next 30 years, up from 2.01 billion tonnes in 2016, increasing by 70%.

Proper waste management not only minimises environmental impact but also offers opportunities for resource recovery and cost savings.

THE IMPORTANCE OF PROPER WASTE MANAGEMENT

Good waste management systems are essential to building a circular economy, and our approach to waste management focuses on the entire lifecycle of our products, which includes process optimisation in our plants where we turn cullet (scraps of glass) into flat glass, actions on packaging (reduce, reuse and recycle), as well as services to customer to manage our products end-of-life. From manufacturing to distribution, from our warehouses to our offices; we reduce waste everywhere.

In our view, there’s no such thing as waste in the future of automotive glazing. Keeping in mind that glass itself never wears out as a raw material (it can withstand endless crush-melt cycles), a fully closed loop in our industry is well within reach. We think proper waste management is not just a responsibility but a significant opportunity for the entire automotive glazing industry. By adopting sustainable waste management practices, we can all minimise our environmental footprint, reduce costs, and contribute to a greener future.

ENGAGING OUR PARTNERS

Achieving a full circular ecosystem within our industry is a collective effort. Which is why we involve all our partners in this important transition, from our suppliers to our customers. For instance, find industrial partners interested in our waste as an example, in Estonia, one of our waste: glass powder from our industrial process is used as a raw material by a road manufacturer. In addition, we encourage best practices for waste management at fitting stations with clear information and proper support. In several countries, we’ve even started collecting waste from our customers.

AN APPROACH THAT HOLDS WATER

In a not so distant future (by 2050), 5 billion people will suffer from insufficient access to water i.e. more than half of the world's population.

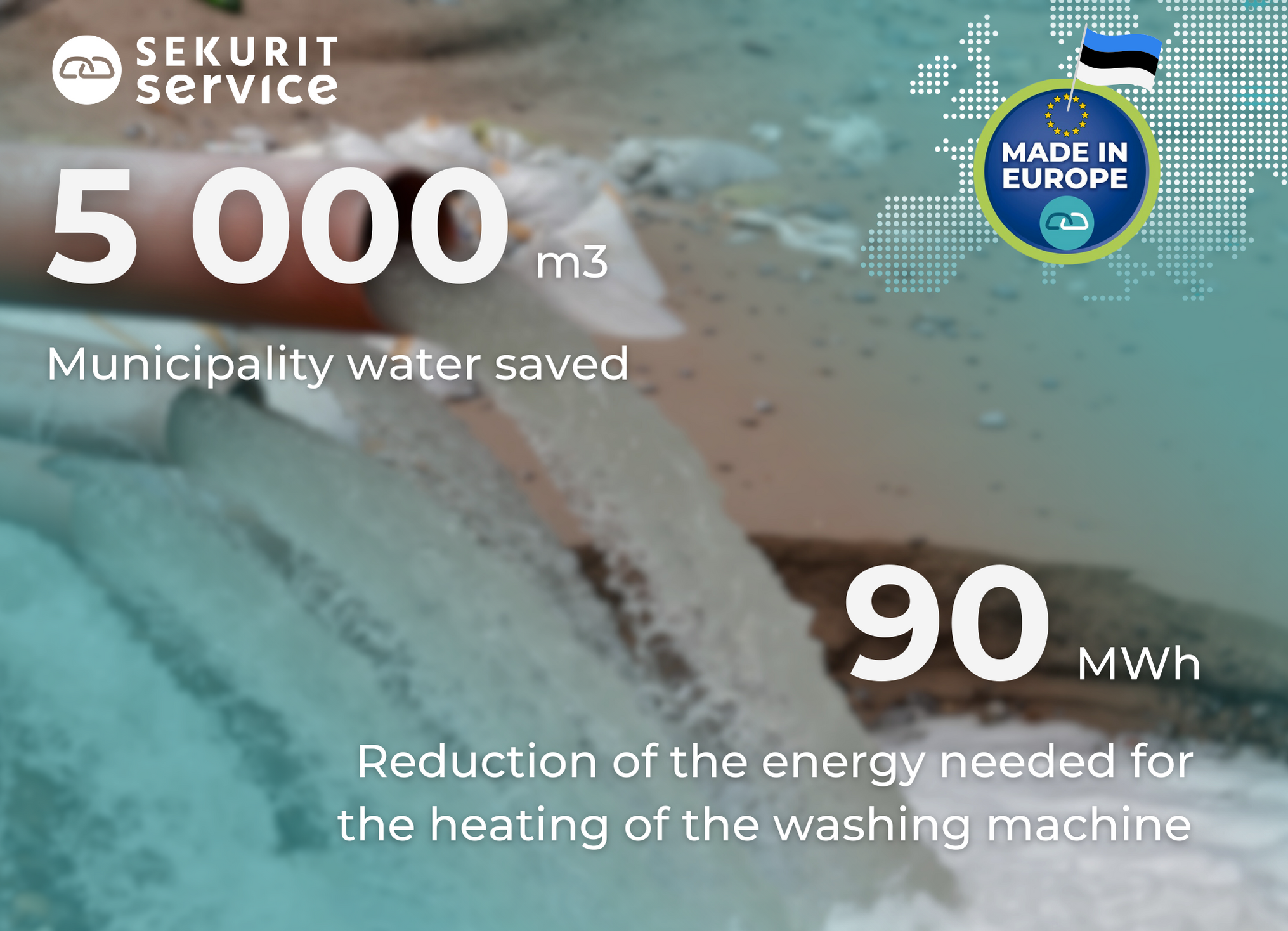

Water, a vital natural resource, is used at different steps in the manufacturing of windscreens. Traditionally, factories use clean water in their production process and dispose of their used water by discharging it back into nature.To improve, our factories are transitioning to an approach where wastewater is recycled back into the production process, thereby closing the water loop.

Last year, we improved our process in our factory in Estonia as their wastewater ended up directly in the Elva River, which is a spawning environment and habitat of salmon, river trout and grayling. They developed an innovative system to collect their wastewater, treat it and reuse it in their production process. This saves a whopping 5.000 m3 of municipality water and reduces the energy needed for the heating of the washing machine by 90 MWh.

BECAUSE WE CARE

As part of the global Saint-Gobain family, Sekurit Service is guided by a shared commitment to ‘make the world a better home’. We’re doing everything we can to reduce our non-recoverable waste to 0 by 2030 and reduce our water withdrawal to preserve natural resources. Why we do it? That’s simple. It’s because we care.

Have you been following our campaign? You can read more here:

#1 - Sekurit Service commitment to sustainability

#2 - Reducing our direct & indirect carbon emissions to zero (more about Scopes 1 & 2)

#3 - Reducing our emissions along the value chain (more about Scope 3)

#4 - Fighting climate change collectively

#5 - More about circular economy and closing the loop

Read more news about Sustainability and CSR (click for more info):

Sekurit Service Sustainability Roadmap

Saint-Gobain Automotive Glazing Replacement receives GOLD EcoVadis Rating

Gold Award for Saint-Gobain Glass Estonia SE Recognition by the Responsible Business Index (VEF)